Trehalose Manufacture Service

Inquiry

What Is Trehalose?

Trehalose was first found in the 1830s. It is an important sugar in which the two glucose units are linked through an α,α-(1,1)-glycosidic bond. The other two isomers of α,α-trehalose are α,β-trehalose and β,β-trehalose. α,α-Trehalose has the lowest conformation energy among the three possible isomers. Besides, it is the most thermodynamically and kinetically stable disaccharide found in nature because of its low energy of glycosidic bond.

Fig.1. Chemical structures of trehalose isomers. (CD BioGlyco)

Fig.1. Chemical structures of trehalose isomers. (CD BioGlyco)

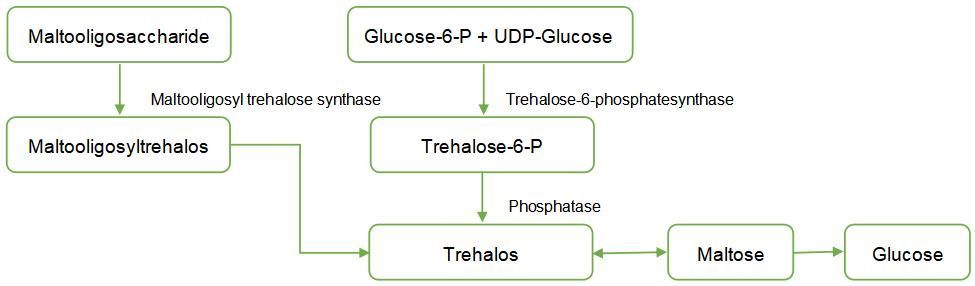

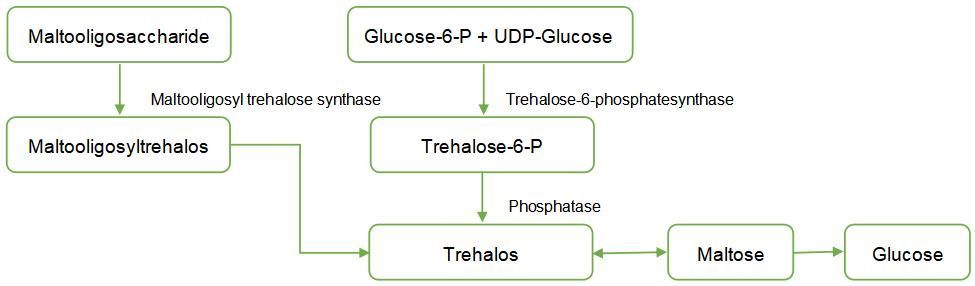

In addition, trehalose lacks reducing properties due to the linkage of D-glucopyranosyl units through their anomeric carbons. Trehalose possesses the ability to protect proteins, lipid membranes, and cells from desiccation, refrigeration, dehydration, and other harsh environments. There are three biosynthesis pathways shown in Fig. 2. It is necessary to produce this disaccharide. As it displays various usages in industries such as food, cosmetics, and medicine, where it serves as a sweetener or a biomaterial stabilizer.

Fig.2. Three biosynthesis pathways of trehalose production. (CD BioGlyco)

Fig.2. Three biosynthesis pathways of trehalose production. (CD BioGlyco)

Trehalose Manufacture Service at CD BioGlyco

CD BioGlyco provides two strategies for the production of trehalose by Enzymatic Process.

- Production of trehalose by immobilization of trehalose synthase

CD BioGlyco employs immobilization techniques to enhance stability, improve activity, raise separation, offer reusable enzymes, and produce more efficient products. We utilize the immobilization of trehalose synthase from Thermus caldophilusutilize on epoxy-activated acrylic bead support for trehalose production from maltose.

Two approaches are useful for the immobilization of trehalose synthase. One involves the binding of enzymes to carriers followed by glutaraldehyde treatment, while the other involves the direct binding of enzymes onto carriers. We find the immobilized enzyme exhibits a wider optimal operating range compared to the free enzyme. That includes enhanced thermostability, an increase in the optimal temperature, and a broader activity/pH profile. These improvements in enzyme properties are crucial for industrial applications. They offer several process advantages, including reduced risk of microbial contamination, lower viscosity, improved conversion rates, and enhanced substrate solubility. We improve the production of trehalose by a continuous process using packed bed bioreactors.

Fig.3 Assay factors before production. (CD BioGlyco)

Fig.3 Assay factors before production. (CD BioGlyco)

- Production of trehalose by the whole cell

CD BioGlyco utilizes the whole cells as biocatalysts in the medium to produce trehalose. Specifically, first, we utilize maltose syrup with high purity as raw material. That effectively excludes impurities from the source and shortens the difficulty of the separation. Besides, we employ a novel trehalose synthase with the highest conversion yield. In addition, instead of employing exchange resin separation, we employ a combination of high-automatic simulated moving bed (SMB) and crystallization technology for the purification of trehalose. This purification method possesses advantages such as low pollution, high efficiency, and simplicity. In conclusion, our whole-cell production method avoids the enzyme purification and immobilization processes and improves production efficiency.

Fig.4 The purification steps of the trehalose. (CD BioGlyco)

Fig.4 The purification steps of the trehalose. (CD BioGlyco)

Applications

- In food industries, trehalose is useful for maintaining the polyphenol content along, the aromatic volatiles, and the color in the food drying or frozen process of fruits and vegetables.

- In the field of cosmetics, trehalose is commonly added to creams and lotions that act as a moisture-retaining agent, enhancing the storage stability of the products. Additionally, it effectively suppresses any unwanted odor emanating from the active ingredients.

- In pharmaceuticals, trehalose plays a key role in preserving tissues and organs for transplantation and cryopreservation of blood stem cells and sperm.

Advantages of Us

- Our production efficiency is remarkably high.

- Our production costs exhibit remarkable affordability, contributing to our operational efficiency.

- Our production methods demonstrate minimal environmental impact, exemplifying our commitment to sustainable manufacturing practices.

CD BioGlyco is clients' ultimate destination for carbohydrate manufacture. With our unparalleled experience, we offer a comprehensive One-Stop Solution for Carbohydrate Manufacture. Our world-class research team ensures unrivaled quality from trehalose to various other carbohydrates. If our solutions capture your interest, we encourage you to promptly contact us for more extensive information.

Reference

- Zheng, Z.; et al. Biocatalytic production of trehalose from maltose by using whole cells of permeabilized recombinant Escherichia coli. PLoS One. 2015, 10(10): e0140477.

For research use only. Not

intended for any clinical use.

Quick Links

Related Services

Fig.1. Chemical structures of trehalose isomers. (CD BioGlyco)

Fig.1. Chemical structures of trehalose isomers. (CD BioGlyco) Fig.2. Three biosynthesis pathways of trehalose production. (CD BioGlyco)

Fig.2. Three biosynthesis pathways of trehalose production. (CD BioGlyco) Fig.3 Assay factors before production. (CD BioGlyco)

Fig.3 Assay factors before production. (CD BioGlyco) Fig.4 The purification steps of the trehalose. (CD BioGlyco)

Fig.4 The purification steps of the trehalose. (CD BioGlyco)