Cold Plasma Treatment

Inquiry

What Is Cold Plasma Treatment?

Plasma processing provides increased energy to the gas through electrical discharge, turning the gas into a high-energy plasma state. These active substances diffuse to the surface and modify the object. Cold plasma technology was mainly used for the sterilization of sensitive materials previously and has now been applied to the food industry as new technology as an alternative to ordinary production techniques, such as starch modification. After cold plasma treatment, the viscosity modulus and elastic modulus of starch increase, and eventually produce a more hydrophilic surface.

Fig.1 Cron starch modified with atmospheric cold-plasma treatment. (Laricheh, et al., 2022)

Fig.1 Cron starch modified with atmospheric cold-plasma treatment. (Laricheh, et al., 2022)

Advantages of Cold Plasma Treated Starch

As a non-thermal physical modification method, Cold plasma treatment has many advantages in various aspects:

- High efficiency, low energy consumption, and less side reaction.

- Low-temperature treatment does not damage the starch granule structure.

- Effectively improve the solubility, relative crystallinity, and gelatinization temperature, and reduce the swelling capacity and viscosity.

- Environmental friendliness and price superiority

- Simple process and easy operation

- High transparency degree of starch products

Cold Plasma Treatment Service

As a burgeoning technology used in starch modification, Cold plasma treatment is being vigorously investigated. CD BioGlyco has the most cutting-edge production technology and the best researchers. We have integrated the following cold plasma treatment mechanisms.

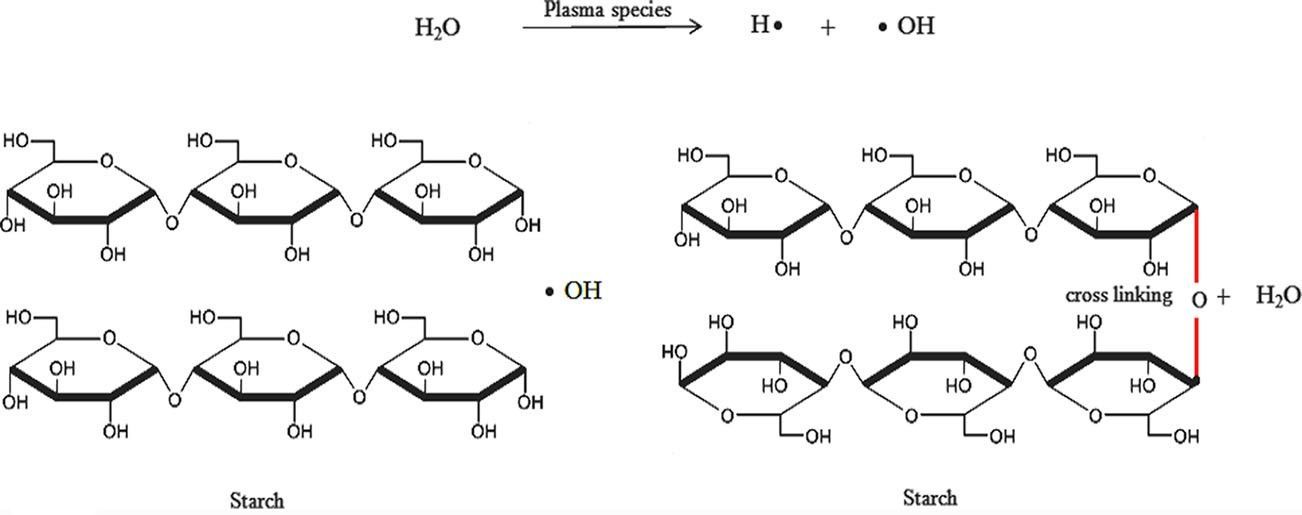

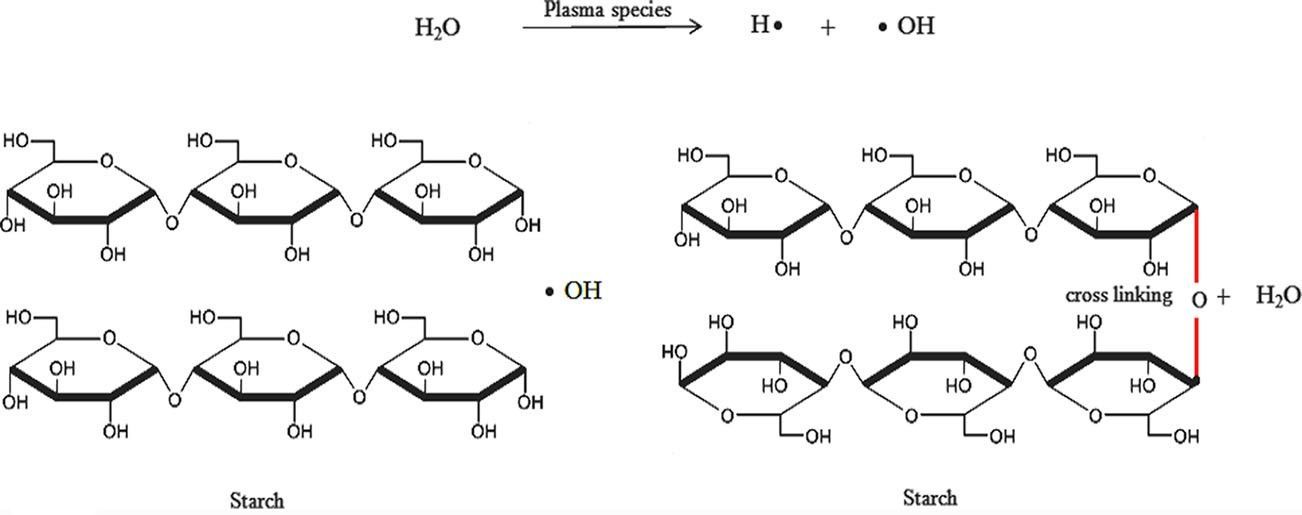

- Cross-linking

The reducing ends of the two polymeric chains (C-OH) are cleaved, resulting in cross-linking due to the removal of water molecules, and a new C-O-C linkage is formed between the two chains. Hydroxy radicals (*OH) formed by the decomposition of water molecules and *OH formed by the oxygen present in the plasma generation process split the glycoside bond.

Fig.2 Mechanism of cold plasma treatment: cross-linking. (Thirumdas, et al., 2017)

Fig.2 Mechanism of cold plasma treatment: cross-linking. (Thirumdas, et al., 2017)

- Depolymerization

The bombardment of plasma high-energy ions causes the amylopectin and amylose side chains of starch to depolymerize and produce smaller fragments.

Fig.3 Mechanism of cold plasma treatment: depolymerization. (Thirumdas, et al., 2017)

Fig.3 Mechanism of cold plasma treatment: depolymerization. (Thirumdas, et al., 2017)

- Plasma etching

During etching, surface materials are selectively etched by physical sputtering or chemical reactions. Radiofrequency (RF) parallel plate plasma systems are the most used plasma systems for etching. The etched surface allows water to enter the starch granules easily, thus altering thermal, functional, and rheological properties.

Fig.4 Mechanism of cold plasma treatment: plasma etching. (Thirumdas, et al., 2017)

Fig.4 Mechanism of cold plasma treatment: plasma etching. (Thirumdas, et al., 2017)

Applications

- Mass modified starch production

- Production of food with low viscosity and high transparency

- Bioethanol production

- Brewing industry development

- Food fermentation

Highlights

- Obtained starch with special characteristics: Low viscosity and high transparency

- Instantaneous high-pressure treatment: Low energy consumption

It is CD BioGlyco's tenet to provide clients with end-to-end quality service. In addition to cold plasma treatment, we provide other Physical Modification services, as well as Chemical Modification, Enzymatic Modification, and Genetical Modification services. If you are interested in our One-Stop Solution for Carbohydrate Manufacture, please contact us for more information.

References

- Laricheh, R.; et al. Corn starch structurally modified with atmospheric cold-plasma and its use in mayonnaise formulation. Journal of Food Measurement and Characterization. 2022, 16: 1859-1872.

- Thirumdas, R.; et al. Cold plasma: an alternative technology for the starch modification. Food Biophysics. 2017, 12: 129-139.

For research use only. Not

intended for any clinical use.

Quick Links

Related Services

Fig.1 Cron starch modified with atmospheric cold-plasma treatment. (Laricheh, et al., 2022)

Fig.1 Cron starch modified with atmospheric cold-plasma treatment. (Laricheh, et al., 2022) Fig.2 Mechanism of cold plasma treatment: cross-linking. (Thirumdas, et al., 2017)

Fig.2 Mechanism of cold plasma treatment: cross-linking. (Thirumdas, et al., 2017) Fig.3 Mechanism of cold plasma treatment: depolymerization. (Thirumdas, et al., 2017)

Fig.3 Mechanism of cold plasma treatment: depolymerization. (Thirumdas, et al., 2017) Fig.4 Mechanism of cold plasma treatment: plasma etching. (Thirumdas, et al., 2017)

Fig.4 Mechanism of cold plasma treatment: plasma etching. (Thirumdas, et al., 2017)