Rhamnolipid Manufacture Service

Inquiry

Characteristics of Rhamnolipids

Rhamnolipid is a kind of glycolipid anionic surfactant, which is a series of homologs consisting of 1-2 rhamnosyl groups and 1-2 β-hydroxy chains with different carbon chain lengths. Rhamnolipids are mainly divided into four categories: monosaccharide mono lipids, monosaccharide lipids, disaccharide mono lipids, and disaccharide lipids. Rhamnolipids are recognized internationally as good oil repellents because of their ability to effectively reduce interfacial forces between oil and water, emulsify crude oil, and change the wettability of reservoir formations. Currently, rhamnolipids can be widely used in medicine, food, agriculture, environmental remediation, and paper making, and even tend to replace chemical surfactants. Based on the above characteristics, the study of the high-yield control strategy of rhamnolipids will promote the manufacture of rhamnolipids to a certain extent, which is of great value for the popularization and application of rhamnolipids.

Fig.1 Biosynthetic pathways of rhamnolipid in Pseudomonas aeruginosa. (Zhao, et al., 2022)

Fig.1 Biosynthetic pathways of rhamnolipid in Pseudomonas aeruginosa. (Zhao, et al., 2022)

Our Technologies

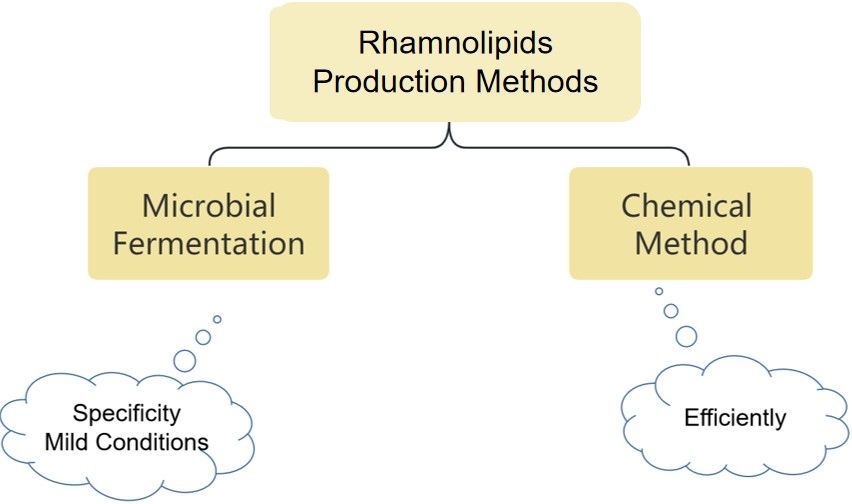

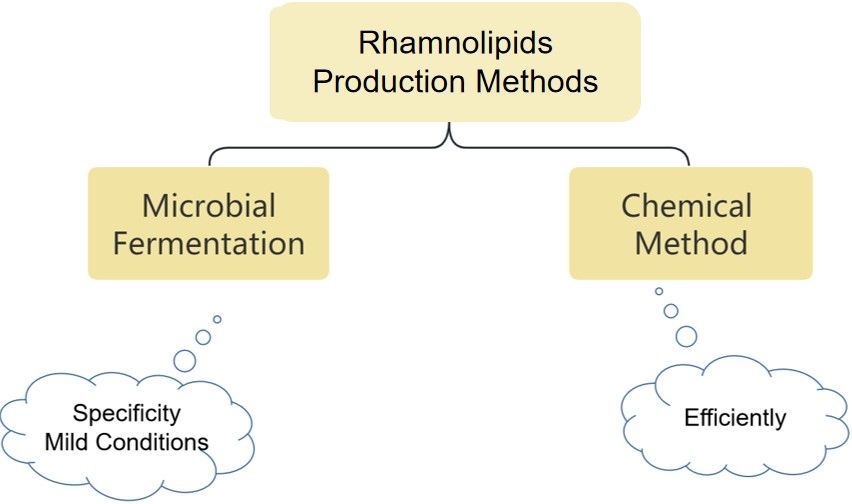

At CD BioGlyco, we produce rhamnolipids using a variety of technologies, including Microbial Fermentation, chemical technologies, and so on.

- Microbial fermentation

Specifically, the fermentation of Pseudomonas aeruginosa is utilized to produce rhamnolipids under different substrates as well as different culture environments. The steps of the production technique are described below.

- Screening of carbon sources

Carbon sources can be categorized into hydrophobic and hydrophilic sources. CD BioGlyco will use both types of carbon sources to produce rhamnolipids. The optimal carbon source is selected by comparing the properties, purity, and yield of the rhamnolipids.

- Screening for nitrogen sources

Nitrogen source is also a nutritional element that affects the manufacturing of rhamnolipids by microorganisms. Rhamnolipids are secondary metabolites, and although organic nitrogen sources are favorable for the rapid proliferation of the bacterium, organic nitrogen sources are not favorable for rhamnolipid synthesis. We have found that nitrate is the best nitrogen source for rhamnolipid production in Pseudomonas aeruginosa.

- Control of the external environment

In addition to the two mentioned above, the external environment is also an important factor in the production of rhamnolipids. CD BioGlyco will use the optimal carbon and nitrogen sources, and design controlled experiments to select the temperature, pH, and oxygen levels that are best suited for the production of rhamnolipids.

Fig.2 Production steps of rhamnolipids. (CD BioGlyco)

Fig.2 Production steps of rhamnolipids. (CD BioGlyco)

In addition to screening conditions for the production of rhamnolipids, we also provide heterologous host synthesis of rhamnolipids as well as regulation of the metabolic pathways of rhamnolipids. For heterologous host synthesis, we introduced rhlAB, the gene encoding the rhamnosyltransferase RhlAB, into the host bacteria to realize host synthesis. For the regulation of metabolic pathways, altering the host gene is a good approach.

- Chemical methods

Chemistry is a well-established technique for manufacturing rhamnolipids. It encompasses several different strategies:

- Solvent method: organic solvents that dissolve both sugars and fats.

- Microemulsification, solvent-free method: the excellent characteristic of being non-toxic.

Fig.3 Production methods for rhamnolipids. (CD BioGlyco)

Fig.3 Production methods for rhamnolipids. (CD BioGlyco)

Applications

- Rhamnolipids have good surface tension, so their production can be applied to the development of surfactants.

- Rhamnolipids emulsify crude oil, so they can be used to produce oil repellents in oil extraction.

- Rhamnolipids can be applied to microbial surfactants because of their degradability and non-toxicity.

Advantages

- The production technology of rhamnolipids helps to explore the development of biosurfactants.

- Rhamnolipids production technology can help to explore the production of carbohydrates.

CD BioGlyco offers a comprehensive range of rhamnolipid production services to help clients explore the properties and uses of rhamnolipids in depth. Our professional research team provides different types of production solutions according to the specific needs of our clients. If you are interested in our services, please feel free to contact us.

Reference

- Zhao, F.; et al. Advances in optimization strategies for microbial high production of rhamnolipids. Microbiology China. 2022, 49(1): 373-382.

For research use only. Not

intended for any clinical use.

Quick Links

Related Services

Fig.1 Biosynthetic pathways of rhamnolipid in Pseudomonas aeruginosa. (Zhao, et al., 2022)

Fig.1 Biosynthetic pathways of rhamnolipid in Pseudomonas aeruginosa. (Zhao, et al., 2022) Fig.2 Production steps of rhamnolipids. (CD BioGlyco)

Fig.2 Production steps of rhamnolipids. (CD BioGlyco) Fig.3 Production methods for rhamnolipids. (CD BioGlyco)

Fig.3 Production methods for rhamnolipids. (CD BioGlyco)