Curdlan Manufacture Service

Inquiry

Where Is Curdlan?

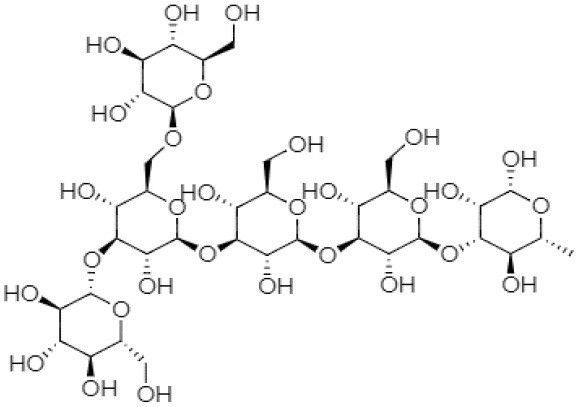

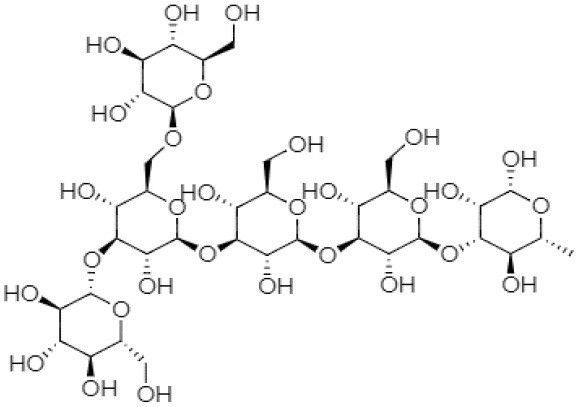

Curdlan is a natural polymer produced by microbial fermentation. It is a kind of microbial exopolysaccharide that is insoluble in water but soluble in alkaline media. Due to its thermal gel properties, curdlan is widely used as a gelling agent in the food, construction, and pharmaceutical industries.

Table 1. Structures of curdlan produced by different bacterial species. (Chaudhari, et al., 2021)

|

Molecular form |

Chemical formula |

Source |

References |

| (1,3)-β-glucans (linear glucan) |

|

Agrobacterium sp. |

Li & Cheung, 2019 |

| (1,3,1,2)-β-D-glucan (branched glucan) |

|

Streptococcus sp. |

Verma, et al., 2020 |

| (1,3,1,6)-β-D-glucan (cyclic glucan) |

|

Rhizobium sp. |

Castellane, et al., 2019 |

Advantages of Curdlan

Curdlan has excellent water retention ability and can be used as a water retention agent. It also has a great film formation property and can effectively prevent the passage of water vapor, suitable to be used as a biodegradable film. Interestingly, curdlan has special rheological properties. When curdlan suspension is heated, it can be divided into two gel types according to different heating temperatures, one of which is a high-set thermal nonreversible gel at about 80°C, and another is a low-set thermal nonreversible gel at about 55°C. this gel property is attributed to the transformation of the helical structure of curdlan at different temperatures. The excellent rheological and thermal properties have led to the application of curdlan as a thickener or fat substitute in the food industry.

Fig.1 Structural changes among three forms of curdlan at different temperatures. (Zhang & Edgar, 2014)

Fig.1 Structural changes among three forms of curdlan at different temperatures. (Zhang & Edgar, 2014)

Curdlan Manufacture Service

CD BioGlyco has an efficient production platform, and our annual output of curdlan exceeds 1000 tons, which can meet the large-scale demand of customers. Our strategies for curdlan production:

- Different sources of curdlan-producing bacteria: CD BioGlyco provides curdlan-producing microorganisms from various sources such as Bacillus from soil, Agrobacterium fabrum from pea plant nodules, Rhizobium from butterfly pea, etc.

- Isolation: The spread plate technique is widely used.

- Screening and identification: We mainly screen the microorganisms through aniline blue medium and identify the strain through 16S rRNA sequencing.

- Fermentation: Submerged fermentation is the frequently-used method, and the product can be easily recovered and purified.

- Optimization of curdlan production: CD BioGlyco explores optimal production conditions by modifying fermentation parameters such as carbon source, nitrogen source, pH, temperature, time, etc.

- Extraction and purification: CD BioGlyco has developed various extraction and purification technologies, including adsorption, chromatography, precipitation, membrane separation, as well as electrodialysis, use of supercritical fluids, ozone purification, and so on.

- Characterization: Characteristics of purified curdlan such as concentration, average molecular weight, thermal gel formation, water retention capacity, and monosaccharide composition will be studied.

Applications

- Food processing: Curdlan is widely used as food additives, with the effect of improving the texture, elasticity, and taste of food.

- Pharmaceutical development: Curdlan derivatives act as modifiers of biological response (anti-tumor, anti-HIV, wound repair).

- Vaccine development: Curdlan is an adjuvant carrier of vaccines.

Advantages

- Optional strategies for curdlan production

- Mass curdlan production capacity

CD BioGlyco has unique advantages in curdlan production and our intimate services are widely acclaimed. We have rich experience in Monosaccharide, Oligosaccharide, and Polysaccharide Manufacture, guaranteeing to provide customers with the best One-Stop Solution for Carbohydrate Manufacture. If you are interested in our services, please contact us for more information.

References

- Li, X.; Cheung, P.C.K. Application of natural β-glucans as biocompatible functional nanomaterials. Food Science and Human Wellness. 2019, 8(4): 315–319.

- Verma, D.K.; et al. Chemistry and microbial sources of curdlan with potential application and safety regulations as prebiotic in food and health. Food research international. 2020,133: 109136.

- Castellane, T.C.L.; et al. Exopolysaccharide produced from Rhizobium spp.-An interesting product for industry and environment. 2019, 3(3): 157-166.

- Chaudhari, V.; et al. Therapeutic and Industrial applications of curdlan with overview on its recent patents. Frontiers in Nutrition. 2021, 8: 646988.

- Zhang, R.; Edgar, K.J. Properties, chemistry, and applications of the bioactive polysaccharide curdlan. Biomacromolecules. 2014, 15(4): 1079-1096.

For research use only. Not

intended for any clinical use.

Quick Links

Related Services

Fig.1 Structural changes among three forms of curdlan at different temperatures. (Zhang & Edgar, 2014)

Fig.1 Structural changes among three forms of curdlan at different temperatures. (Zhang & Edgar, 2014)