Galactooligosaccharide Manufacture Service

Inquiry

What Are Galactooligosaccharides (GOS)?

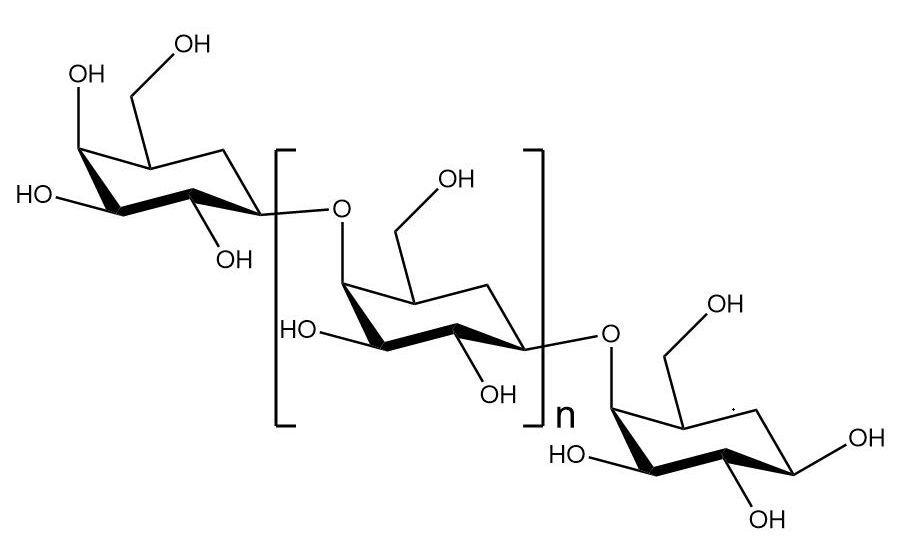

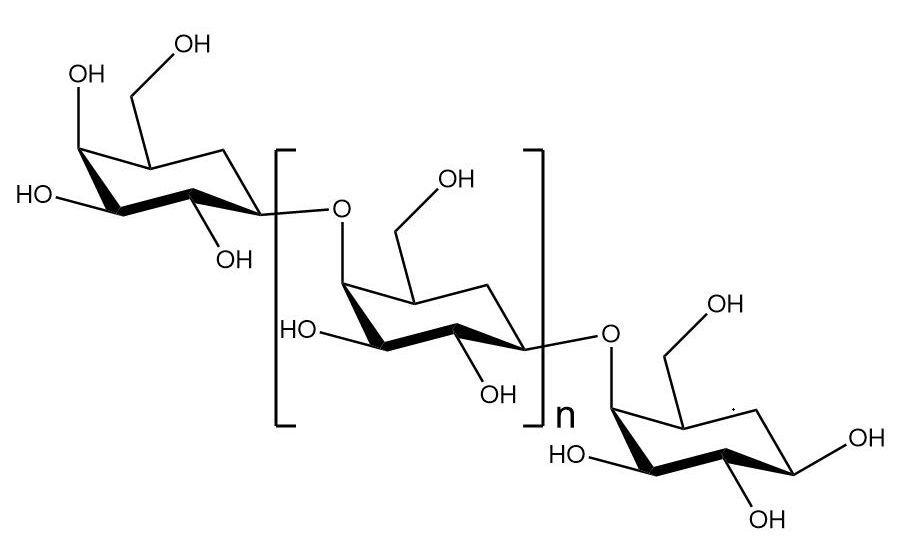

GOS belong to the class of prebiotics that act as food for "good" bacteria in the intestine. Before digestion, they reach into the colon where they increase bowel mass. It has been shown that GOS effectively stimulates the growth of Bifidobacteria in the gut, as well as Lactobacilli and Bacteroidetes. Bifidobacteria are considered highly beneficial to the human host due to their ability to produce short-chain fatty acids (SCFAs). GOS are the third most prominent component in human breast milk after lactose and fat. Therefore, GOS is used in infant formula to better simulate human breast milk. GOS structures are different in saccharide composition, regiochemistry of the glycosidic linkages, and the degree of polymerization. Besides, prebiotic microbes grow differently when exposed to oligosaccharides of different structures. In addition, the structure of GOS also influences characteristics relevant to their utilization in food applications.

Fig.1 Chemical diagram for GOS. (CD BioGlyco)

Fig.1 Chemical diagram for GOS. (CD BioGlyco)

GOS Manufacture Service at CD BioGlyco

CD BioGlyco provides two ways for the production of GOS by Enzymatic Process. We use β-galactosidase to catalyze enzymatic trans-galactolysis. The β-galactosidase is either soluble or immobilized. It is isolated after intra- or extracellular expression, or provided within whole cells.

- Production of GOS by whole cells as biocatalysts

We utilize resting or living whole cells to produce GOS that doesn't need the isolation of the β-galactosidase enzyme. Protein isolation is challenging and costly and needs additional processing procedures after breeding the β-galactosidase-producing organism. Our approach avoids those problems effectively. The field of GOS in this production method is comparable to the GOS field in those approaches with isolated enzymes.

Fig.2 Production steps by whole cells as biocatalysts. (CD BioGlyco)

Fig.2 Production steps by whole cells as biocatalysts. (CD BioGlyco)

- Production of GOS by membrane processing

We also offer an alternative approach to product GOS by membrane processing. The cost of this method is ameliorated by recycling the biocatalyst. We employ an ultrafiltration (UF) approach to achieve enzyme recycling. In this method, a semi-permeable membrane is used to trap the larger enzyme inside the bioreactor while permitting the passage of smaller molecules, such as substrate and product. We continuously remove the product saccharides and replace them with fresh substrate. That allows the reaction to be continued indefinitely and the integrity of the bioreactor to be maintained. Besides, UF membranes control the average amount of lactose exposure to β-galactosidase. Controlling this parameter is crucial since it directly impacts both the yield and structure of GOS. The process is shown in the following picture.

Fig.3 Production steps by membrane processing. (CD BioGlyco)

Fig.3 Production steps by membrane processing. (CD BioGlyco)

Applications

GOS can be widespreadly applied in various food products, including infant milk formula, follow-on formula, and infant foods.

GOS is used in meal replacements, fermented milks, flavored milks, confectionery products, zero-fat yogurt, and bakery items such as bread, cakes, and cookies.

GOS can be used in a range of beverages, including fruit juices, other acidic drinks, baby juice, sports drinks, and lactobacillus beverages.

GOS can be used in the pharmaceutical industry for various purposes, such as relieving constipation, promoting the growth of bifidobacteria, aiding in satiety and weight management, and improving cholesterol levels.

Advantages of Us

- We utilize resting or living whole cells to produce GOS, eliminating the need for the isolation of the β-galactosidase enzyme.

- By utilizing whole cells, we avoid the challenging and costly process of protein isolation that is required in other production methods involving isolated enzymes.

- We employ membrane processing, specifically UF, to recycle the biocatalyst, reducing costs associated with enzyme usage.

CD BioGlyco is a prestigious company in the field of carbohydrate bioscience. Our research team specializes in providing an all-encompassing solution for GOS manufacturing services. With a dedicated team of experts, we offer a comprehensive range of services for all your carbohydrate manufacturing needs. In a word, CD BioGlyco provides a One-stop Solution for all Your Carbohydrate Manufacturing requirements. If you find our services intriguing, do not hesitate to contact us promptly for further detailed information.

Reference

- Cao, T.; et al. Continuous production of galacto-oligosaccharides by an enzyme membrane reactor utilizing free enzymes. Membranes. 2020, 10(9): 203.

For research use only. Not

intended for any clinical use.

Quick Links

Related Services

Fig.1 Chemical diagram for GOS. (CD BioGlyco)

Fig.1 Chemical diagram for GOS. (CD BioGlyco) Fig.2 Production steps by whole cells as biocatalysts. (CD BioGlyco)

Fig.2 Production steps by whole cells as biocatalysts. (CD BioGlyco) Fig.3 Production steps by membrane processing. (CD BioGlyco)

Fig.3 Production steps by membrane processing. (CD BioGlyco)